Why Particle board?

There are various advantages of Particle Boards over plywood, wood and MDF. The apprehensions are generated by the people who are not aware of the properties and those who opinionate on what they hear or those who have been witness to the cheap quality of Particle Board products. Some reasons industry experts recommend Particle Boards are:

- Over 90% of the mass-manufactured furniture is made of Particle Board as the biggest advantage of using Particle Board is that it is an industrial product. It is an ideal raw material when compared to solid wood as wood requires more manual labor while Particle Board works efficiently with machines.

- The conversion time is much less as compared to post lamination

- Particle Board is more affordable as compared to plywood and wood

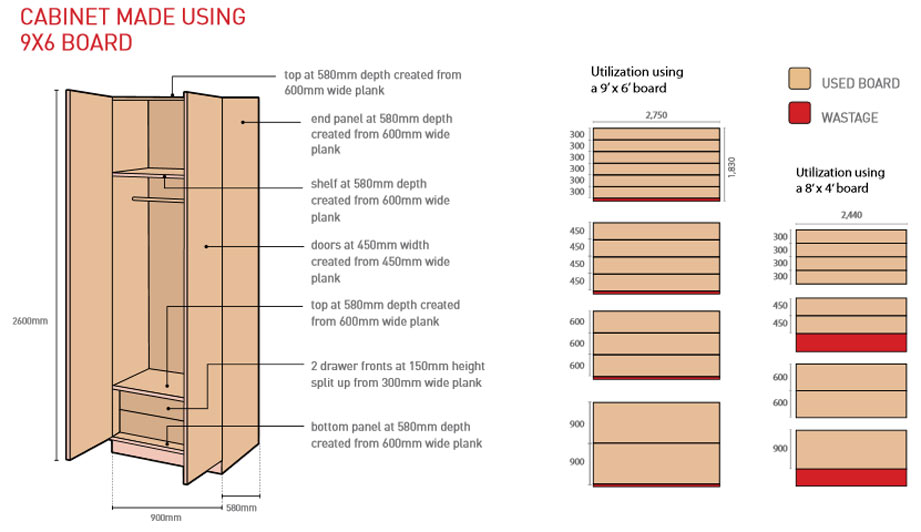

- Bigger size availability in Particle Boards gives seamless finish for wardrobes and furniture and flexibility in design is also a plus

- Thickness options in Particle Boards are from a mere 6mm to 40mm

- The myth that Particle Board may not give strength in case of chairs has also been disproved by many leading brands

- In the new look of the home or office, there's no room for excess. This has kept furniture minimal and elegant. Straight or curved lines, with a minimum of fuss hence Particle Boards fit very well with such design and construction.

- Particle Board is denser and more uniform than natural wood and plywood. Different grades of Particle Board have different densities. The higher the density, the greater is the strength and greater is the resistance to failure of screw fasteners.

- Particle Board is a little cheaper because the consumption of energy is lower as the processes are fewer than when MDF is used yet it is an equally good product

- A very important advantage is economy and environment friendliness. The efficiency of timber usage is as low as 20 percent in the case of solid timber and 40 to 50 percent in the case of plywood. But in the case of Particle Board, the usage of timber is 120 to 150 percent as only the branches are cut to make Particle Board.

- Many manufacturers prefer Particle Board as it never has inherent defects like any other wood-based products or wood. The screw holding strength in Particle Board is standard where as in case of other wood-based products it may vary, which may affect the designing process.